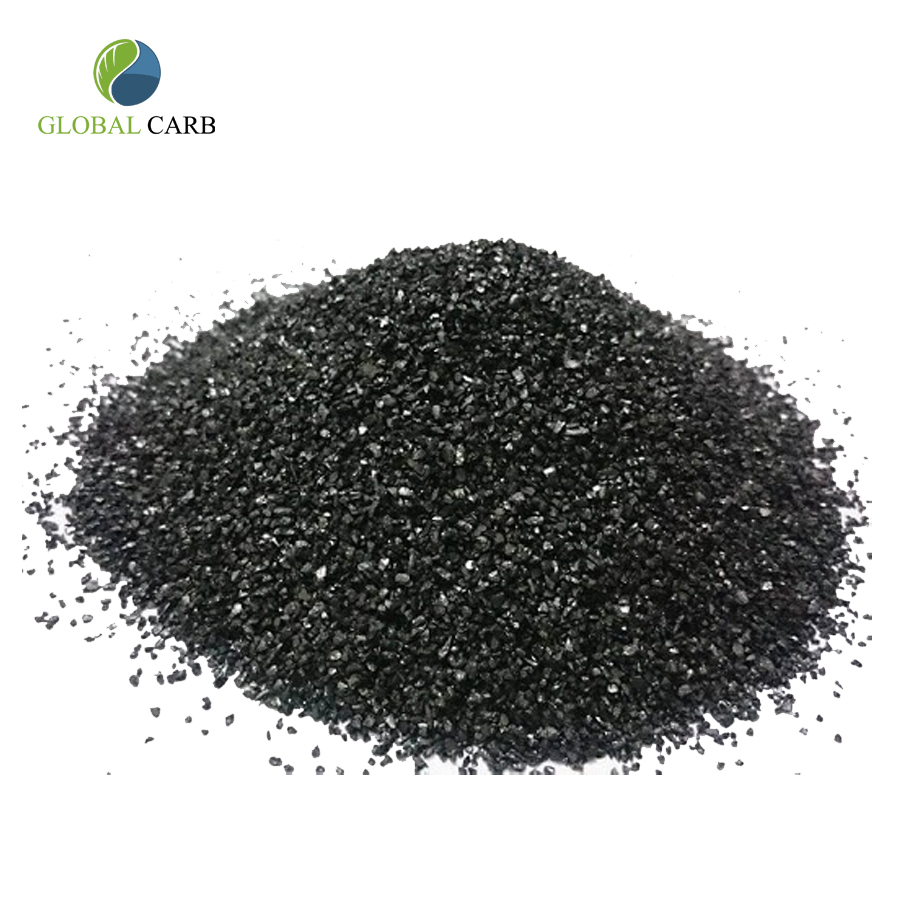

Than Hoạt Tính Chất Lượng Cao, Giá Tốt

Công ty Than hoạt tính CP đầu tư xây dựng và khai thác chuyển giao công nghệ chuyên cung cấp than hoạt tính Việt Nam chất lượng cao với giá thành tốt nhất sử dụng trong lọc nước, lọc khí, lọc màu thực phẩm như than hoạt tính gáo dừa, than gáo dừa bến tre, đất sét hoạt tính, Than Anthracite và các sản phẩm khác

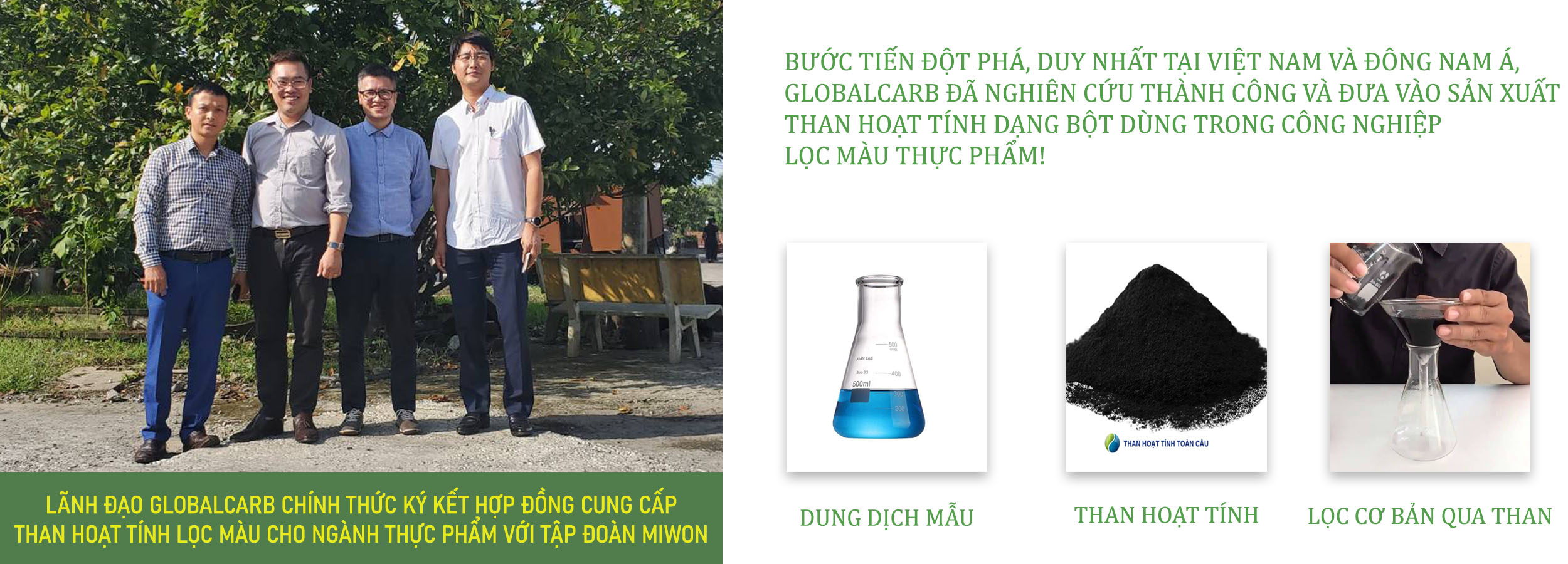

Than hoạt tính lọc màu

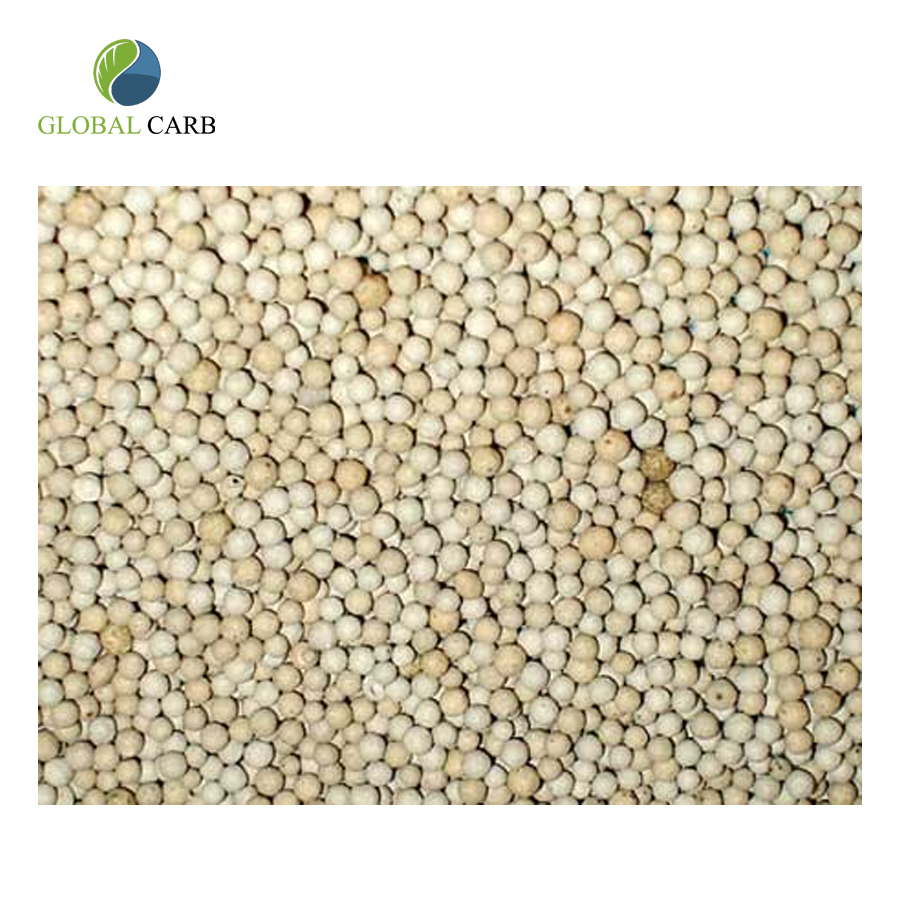

Than hoạt tính gáo dừa dạng hạt

Than hoạt tính gáo dừa dạng bột

Than hoạt tính viên nén

Than hoạt tính từ gỗ dạng bột

Than Anthracite (than Antraxit)